The sound barrier series is divided into reinforced and non reinforced sound screen panels. In addition, reinforced panels are available in black and white, and various colors can be customized to meet customers' various requirements from multiple aspects.

The sound barrier series is divided into reinforced and non reinforced sound screen panels. In addition, reinforced panels are available in black and white, and various colors can be customized to meet customers' various requirements from multiple aspects.

Suggestion

Usage suggestions

1. Wind load

In the design phase of the sound screen project, the following factors should be fully considered

1. The situation on site, such as whether there will be strong winds (even occasionally)

2. Owners' technical requirements

3. Local relevant laws and regulations.

2. Fixed

According to current regulations and testing standards, acrylic sound screen panels should be fixed with appropriate frame surfaces, otherwise the sound screen panel may become excessively loose in strong winds, and in some extreme cases, may even detach from the frame.

3. Thermal expansion

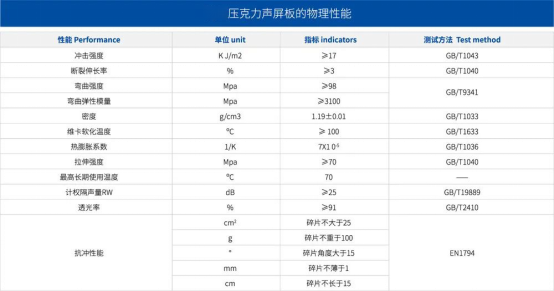

Like most plastic materials, the thermal expansion of full glass acrylic sound screen panels is slightly higher than that of traditional building materials, usually 7X1 0-5. This should be considered when designing the fixing frame (see "fixing" for evaluation). In addition, factors such as cutting accuracy, sheet size tolerances, and moisture absorption should also be considered. It is recommended to leave a total thermal expansion of 5 millimeters per meter during installation, as shown in the table below.

4. Compatibility of auxiliary materials

Materials that come into direct contact with acrylic sound screen panels, such as rubber sealing strips, may come into long-term contact with the acrylic panel. Therefore, compatibility with acrylic materials should be considered, otherwise it may cause local brittleness or even cracking of the sound screen panel.

The materials that may cause damage to acrylic sound screen panels include plasticized PVC, peroxide vulcanized EPDM (ethylene propylene diene monomer rubber), and silicone containing acetic acid.

Acrylic is a plastic polymer material. When selecting materials, it is necessary to choose acrylic sheets that are brand new and have relevant performance parameters that meet the requirements of the national standard GB/T 7134-2008. Otherwise, some performance and weather resistance cannot be guaranteed. Under normal usage conditions, the fading is not significant within three years (except for specially designated indoor color boards). The performance parameters of the new acrylic material are shown in the following table:

-

Performance ProjectTechnical ParameterNotes

-

Thickness tolerance/mm+0.54-5mm

-

Tensile strength/Mpa≥70

-

Tensile modulus of elasticity/Mpa≥31001

-

Rockwell hardness/M scale≥98

-

vicat/C≥105

-

Flame retardant gradeB2-E

-

Elongation at break/%≥4

-

After 10 years of use, the transmittance decreases/%≤10Completed 10000 hours of rapid aging test, equivalent to 20 years outdoors